Companies often maintain their assets reactively and repair or replace an asset only after it has already broken down. This is known as reactive maintenance. Reactive maintenance is problematic and is frequently associated with equipment breakdowns, which disrupts operations and leads to substantial losses. Reactive maintenance also leads to, amongst others, sub-optimal overall equipment efficiency. Companies must therefore plan maintenance activities based on exact data concerning the status of the assets, rather than based on hypothetical end of life values to ensure optimal overall equipment efficiency.

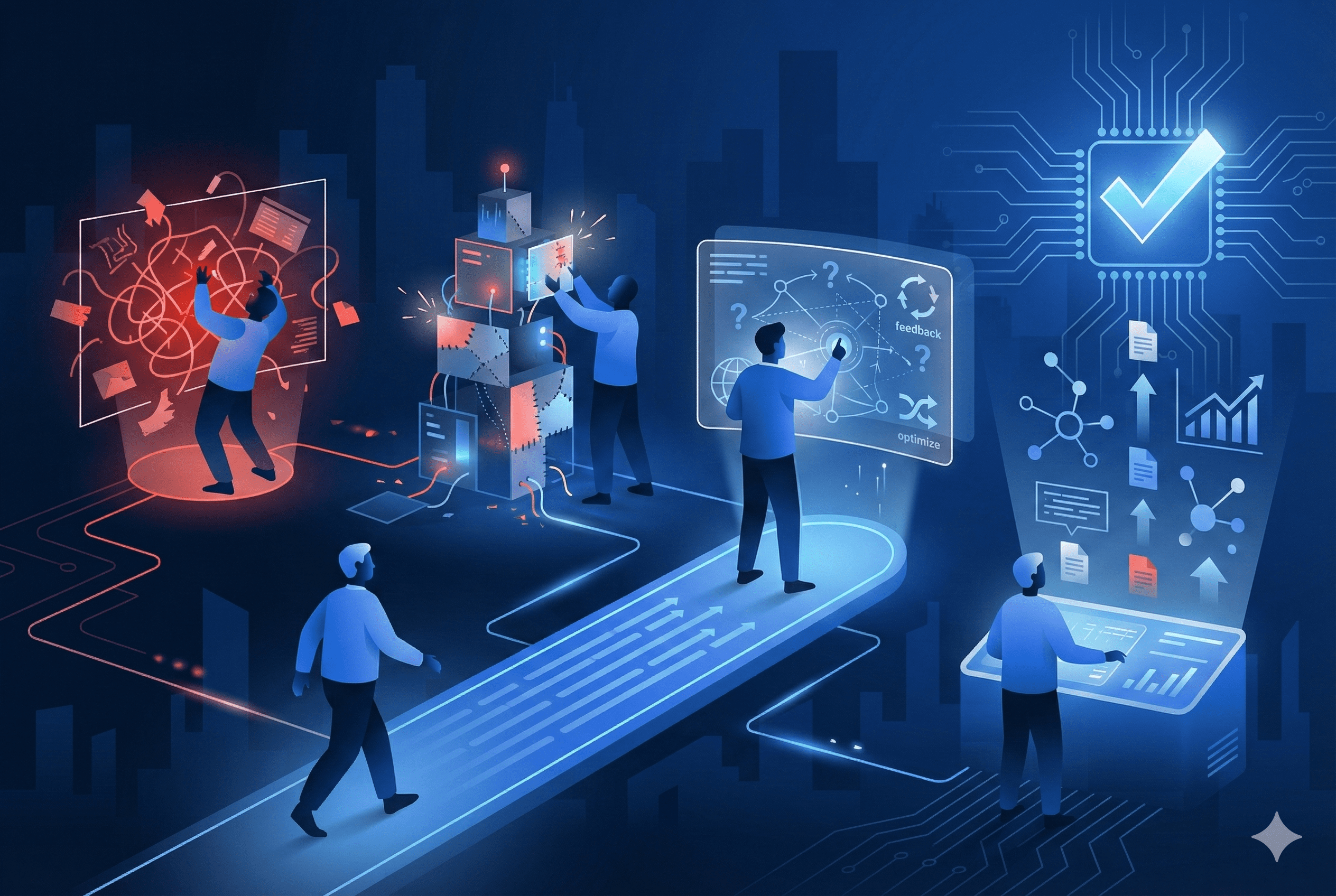

To mitigate the inefficiencies of reactive maintenance, industrial organisations transitioned to preventive maintenance. In terms of this model, machine operators and factory managers manually scheduled repairs to machinery and equipment to avoid downtime. Still, 50% of these preventive maintenance activities were ineffective. Given the above, predictive maintenance emerged as an Industry 4.0 use case for manufacturers where maintenance activities were scheduled based on predictive maintenance instead of preventive maintenance. Below we discuss briefly the elements of predictive maintenance.

- Predictive maintenance in a nutshell

- How does predictive maintenance work?

- Predictive maintenance and Industry 4.0

Scheduling based on predictive maintenance data is more cost-effective, more accurate and prevents more breakdowns than in a preventive maintenance mode. Research conducted by Market Research Future estimates that the predictive maintenance market will globally “reach $6.3 billion within the next two years.” Predictive maintenance is, essentially, “the gold star of the maintenance world—it ensures that tasks are performed at just the right time. Unlike preventive maintenance, there is no risk of performing too much or too little maintenance work with predictive maintenance.”

1. Predictive maintenance in a nutshell

Predictive maintenance, also known as condition-based maintenance, is a proactive maintenance strategy that monitors the condition and performance of assets in real time so as to predict, before breakdown, when an asset will require maintenance. According to the United States Department of Energy, a practical and well-designed predictive maintenance programme can increase return on investment (ROI) up to ten times while reducing downtime by a massive 75%.

2. How does predictive maintenance work?

Predictive maintenance combines sensors, Internet of Things (IoT), machine learning, data analytics and modelling to determine whether there are any warning signs of imminent machinery or equipment failure. This approach removes the guessing factor since maintenance can be scheduled when machinery or equipment needs it.

Predictive maintenance, when implemented correctly and used often can help you avoid costly repairs and equipment downtime and, ultimately, save your business millions of rands. In fact, downtime as a result of machine failures can be more costly than the actual machines breaking.

3. Predictive maintenance and Industry 4.0

At the heart of Industry 4.0 lies the ability to automate processes using connected devices that can collect, send, and receive data. In this manner, technology is unlocking data and insights that were previously inaccessible and is so opening the doors to improved data analysis and operational insights. Its goal is also to increase the amount of usable data to facilitate improved decision making. However, the timeous delivery of and access to data is network-dependent and networking technology and manufacturing processes must advance to manage more data. Interconnected automation needs connected machines to collect and share information. How these machines communicate through networks makes Industry 4.0 possible. Industry 4.0 in manufacturing or Manufacturing 4.0 is driven by capital, assets, and operational efficiency. When implemented properly, Manufacturing 4.0 will deliver improved information, automation, and the ability to intervene on a predictive basis leveraging the five different layers of IoT systems integration — connected sensors, centralised data, actionable insights, workflow automation and predictive insights.

Downtime is still the single largest source of lost production time for most manufacturers. According to AspenTech, “[t]he vast majority of manufacturing downtime is caused by process or equipment failures. These emergent causes of unplanned downtime account for 80% of manufacturing downtime.” Implementing predictive maintenance offers several benefits such as reduced maintenance costs and improved production, maximised machinery and equipment lifespans, decreased downtime and lost-time incidents, enhanced customer service, and increased revenue as predictive maintenance protects your valuable assets.

The question therefore becomes: Can you really afford not to implement predictive maintenance?

DOWNLOAD FREE GUIDE:

A disruptive approach to reducing manufacturing breakdowns by 75%