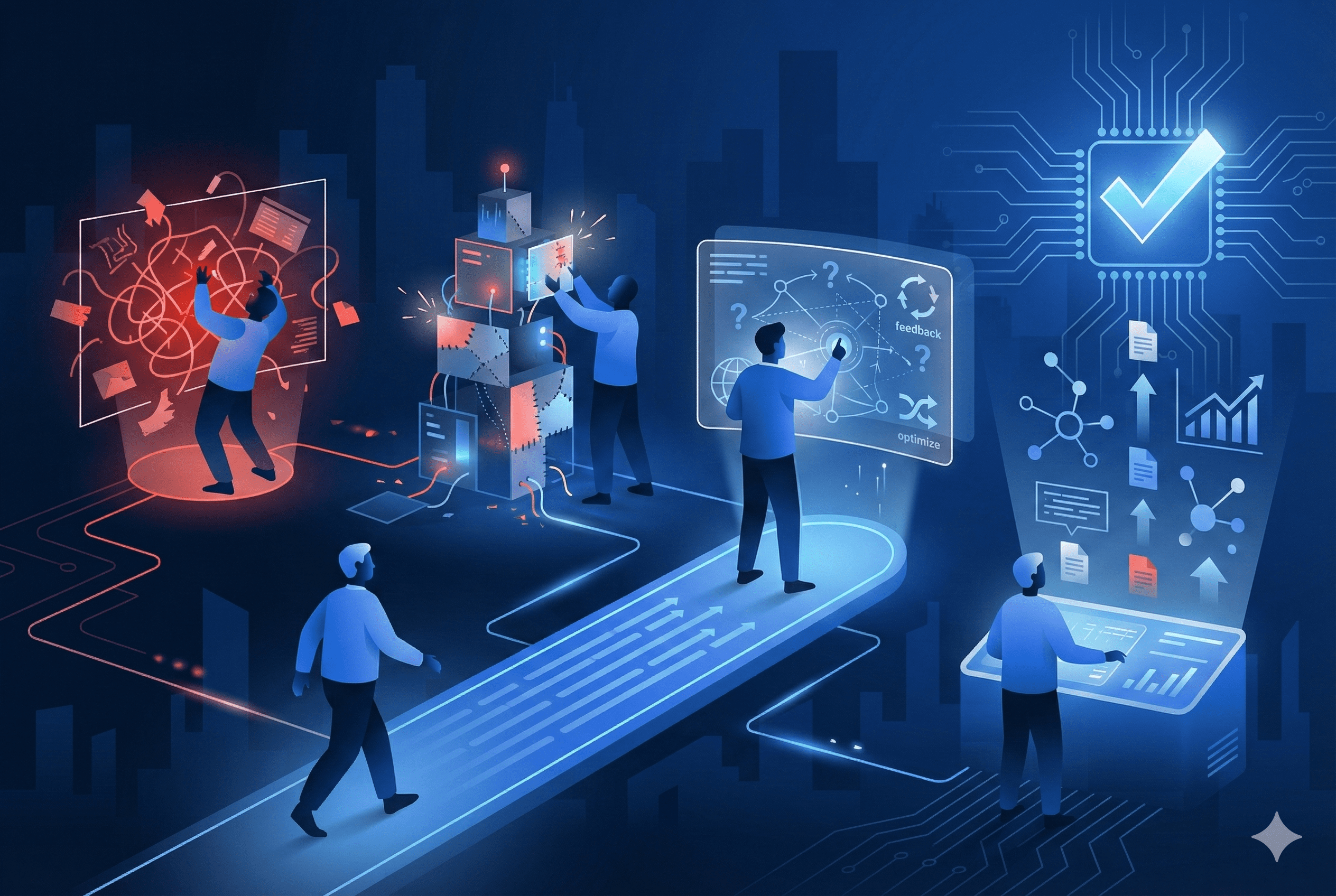

Unplanned downtime is mostly caused by human error, poor maintenance, hardware or software issues whereas ‘perceived downtime’ includes poor performance or slow changeover. According to the Wall Street Journal, “Unplanned downtime costs industrial manufacturers an estimated $50 billion annually. Unplanned outages result in excessive maintenance, repair and equipment replacement.” Indeed, equipment failure is the cause of 42% of unplanned downtime which results in excessive maintenance, repair, and equipment replacement. Preventing equipment failure can be best explained using the predictive maintenance process flow model:

1. Establish conditional baselines

2. Install condition monitoring sensors

If the predictive maintenance process flow is executed correctly, your operations will soon see a significant improvement. It might take a few months to kick in depending on the size of your plant or operations and the amount of machine or equipment downtime that was happening before employing the predictive maintenance model.

1. Establish conditional baselines

Step one of employing predictive maintenance is establishing conditional baselines. This is done by monitoring assets’ conditional baselines and collecting data about these baselines before installing sensors. That way, when you begin to collect conditional data, there is a benchmark to compare any abnormalities to.

2. Install condition monitoring sensors

Thereafter, condition monitoring sensors are installed on machinery and equipment to monitor and collect data about its operations. For example, a vibration meter is affixed to a piece of equipment and a temperature sensor is attached to a boiler. It should be noted that often sensors are already pre-installed on machines and equipment.

3. Collect conditional data

For this step, an IoT device is connected to, for example, a Computerised Maintenance Management System (CMMS) or remote dashboard where the collected data is analysed.

4. Identify baseline breaches

By applying machine learning and artificial intelligence algorithms, baseline breaches, as well as the events that caused or preceded them, can be detected. Any abnormalities or inconsistencies will be detected much earlier than would have been possible by human observation. Next, a proper work order can be created to schedule maintenance.

5. Perform maintenance

After following the above steps, it becomes simpler: Any time a piece of equipment or machine performs outside of normal parameters, the sensors trigger your predictive maintenance protocol and maintenance can be scheduled.

Predictive maintenance is an ‘intelligent way to maximise machine availability.’ Having the correct data at the right time, it is possible to determine the condition of in-service machinery and equipment and then to predict when maintenance should be performed. As a result, it is possible to conveniently schedule corrective maintenance actions and so prevent equipment failure. The value of predictive maintenance – and the role it plays in preventing equipment failure – therefore lies in its cost-saving and/or time-saving approach, as maintenance is only performed when needed.

DOWNLOAD FREE GUIDE:

A disruptive approach to reducing manufacturing breakdowns by 75%