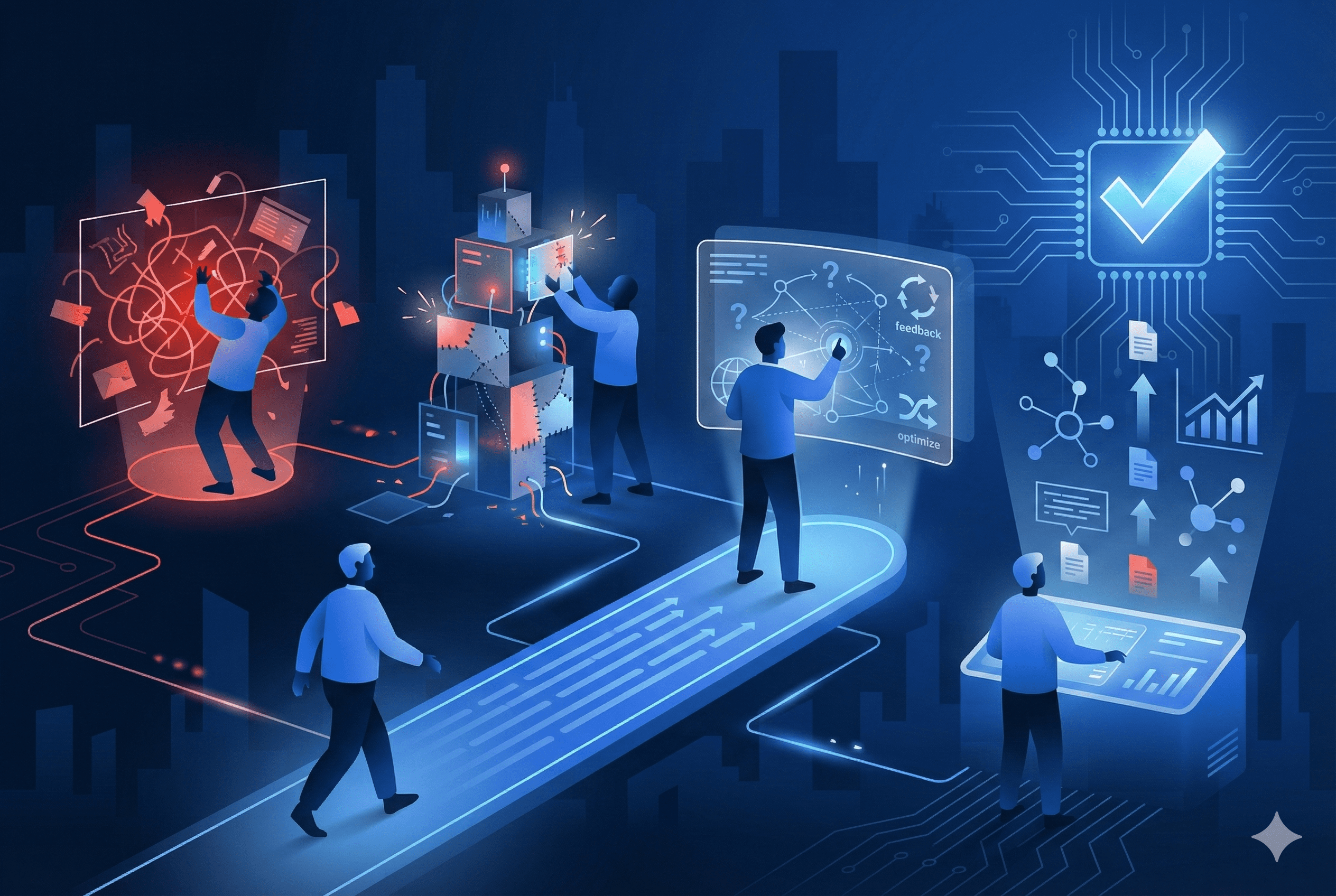

Predictive maintenance systems are automated and therefore do not need human skills to perform their function— to determine when machinery and equipment should be maintained. This does not mean you do not need your workforce or that machines will take away jobs. On the contrary, switching to predictive maintenance presents an opportunity to empower unskilled labour to deliver value. In this post we take a look at some of the opportunities associated with utilizing predictive maintenance:

1. It reduces maintenance costs and production downtime

2. It has the potential to create new jobs

3. Smaller companies can start with predictive maintenance too

In South Africa (a country that desperately needs to create jobs), businesses are grappling with fears that technology, machine learning and artificial intelligence will destroy more jobs than it creates. However, it is arguable that digitisation has enormous potential to create jobs and not take it away. For example, unskilled labour can be trained and promoted to roles that require them to manage or deploy AI/machine learning IoT-based technologies.

1. It reduces maintenance costs and production downtime

A recent study conducted by Accenture and GE found that predictive maintenance for South African enterprises can generate a 30% reduction in maintenance costs and an up to 70% decrease in production downtime caused by equipment breakdowns.

2. It has the potential to create new jobs

In terms of employment, the McKinsey Institute in their research paper, The Future of Work in South Africa, estimates that ‘digitisation, machine learning and automation have the potential to create 1.8 million new jobs purely as a result of improved productivity – which in turn could increase income levels, consumer spending, investment in construction and infrastructure, and spending on education and health care.’ Furthermore, approximately 1.2 million new jobs will be created from as yet unknown occupations that will be created as a result of disruptive technology.

3. Smaller companies can start with predictive maintenance too

In addition to the above, as the costs of sensors, computing power, cloud storage and bandwidth are decreasing yearly, smaller companies can get started with predictive maintenance. Even though there will be an initial investment, you can expect to see a tenfold ROI on your predictive maintenance investment within the first 2 years. Although a global statistic, you can also expect to see a further maintenance cost reduction of 30% according to the U.S. Department of Energy.

Implementing predictive maintenance and the initial investment to do so might seem daunting, but the ROI certainly far outweighs implementation fears and upfront costs. And finally, apart from improving ROI and creating jobs, it also results in competitive differentiation.

DOWNLOAD FREE GUIDE:

A disruptive approach to reducing manufacturing breakdowns by 75%